Vibration Analysis

Standard balance tests are performed on all complete fan assemblies – size permitting. This ensures that there are no noticeable mechanical defects such as rubbing, bearing noise or excessive bearing heat and the vibration levels filtered into the running speed are reported. TCF can also provide vibration reports that include the filtered and overall levels if requested. Customers often require longer run tests to allow the bearing temperatures to stabilize. In order to achieve the stabilized temperatures, TCF will run the fan for two hours and record both the bearing temperatures and bearing vibration levels every 15 minutes – or as specified.

When specifications call for the detrimental resonant frequencies in a fan assembly to be identified, TCF can perform a coast down test. Coast down testing involves running the fan up to the desired speed and then decelerating slowly. By recording the vibration levels until the fan comes to a stop, the detrimental resonant frequencies can be identified. In addition to these standard tests, TCF is able to test to any vibration specification that a customer requires.

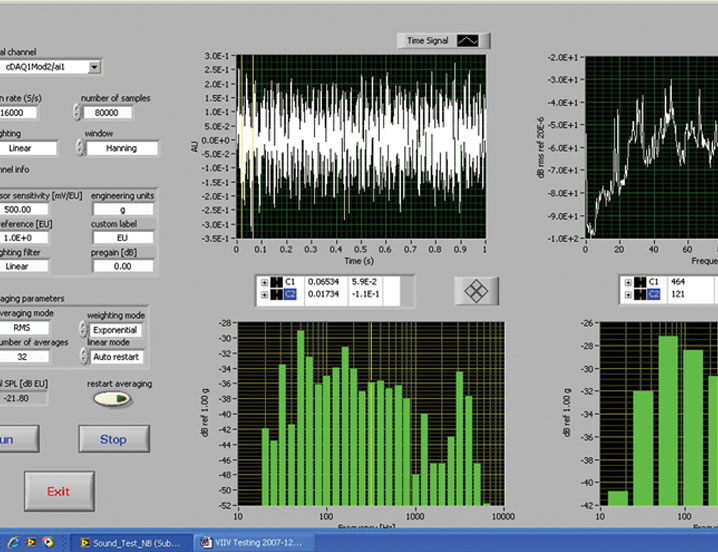

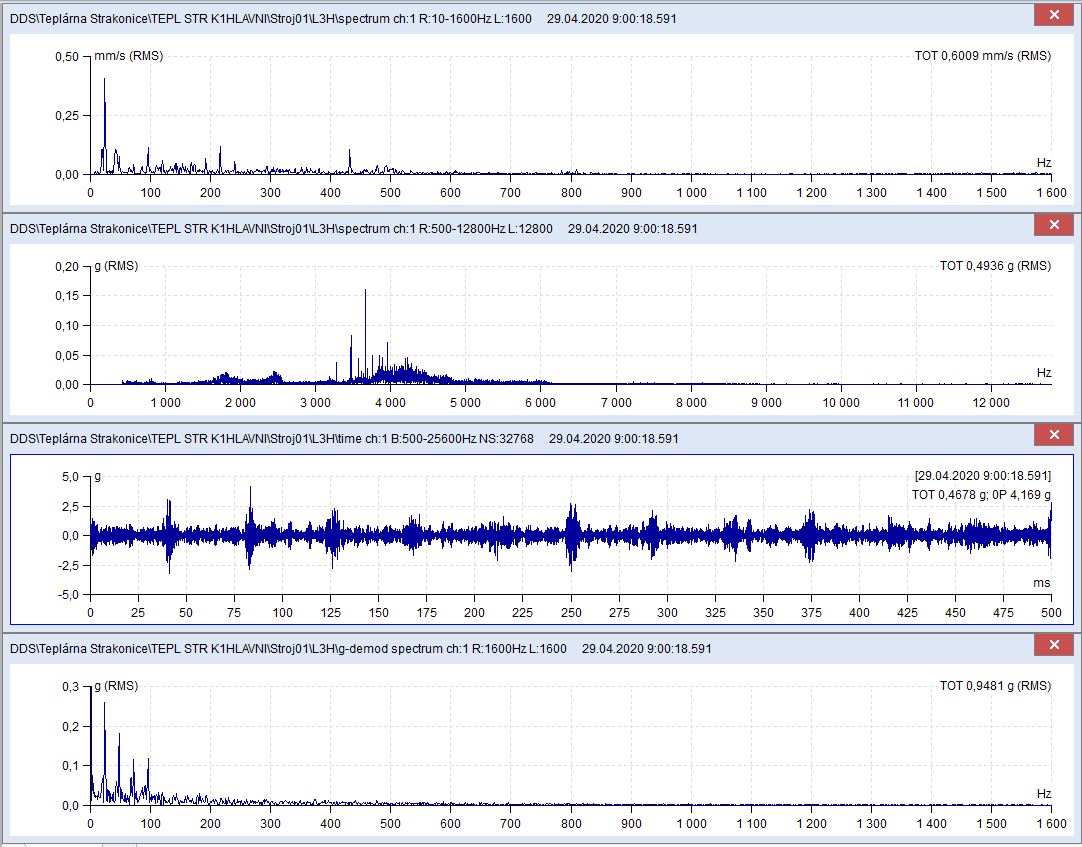

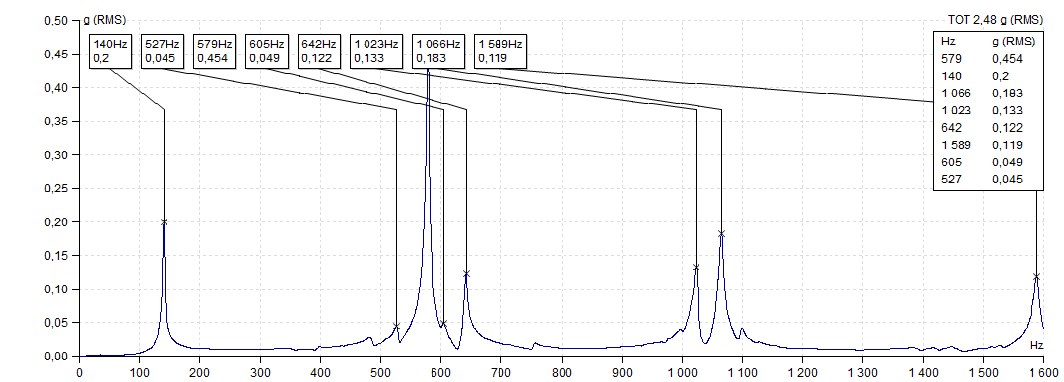

We use ADASH Analyser.

VA4 Pro II is a professional 4/4 channel signal analyzer built especially for vibration analyst who has the highest expectations of their equipment. With up to 90 kHz frequency range, raw signal recording and many special measurements such as full spectrum, the VA4 Pro II fulfills all vibration analysts measurement needs.

Balancer – 1 and 2 plane on site balancing

Run up – run up and coast down measurements

Recorder – raw signal recording for later post analysis

Stethoscope – listening of the bearing/machine noise

FASIT – expert system for automatic fault detection

Octave analyzer – hearable sound measurements

Bump test – measurement of natural frequencies

ADS – Animated Deflection Shapes (Operating deflection shapes)

Vibrations analysis

Bump test

Animated Deflection Shapes